GUYED TOWERS

World Tower provides the communications industry the most reliable, economical guyed tower systems in the business.

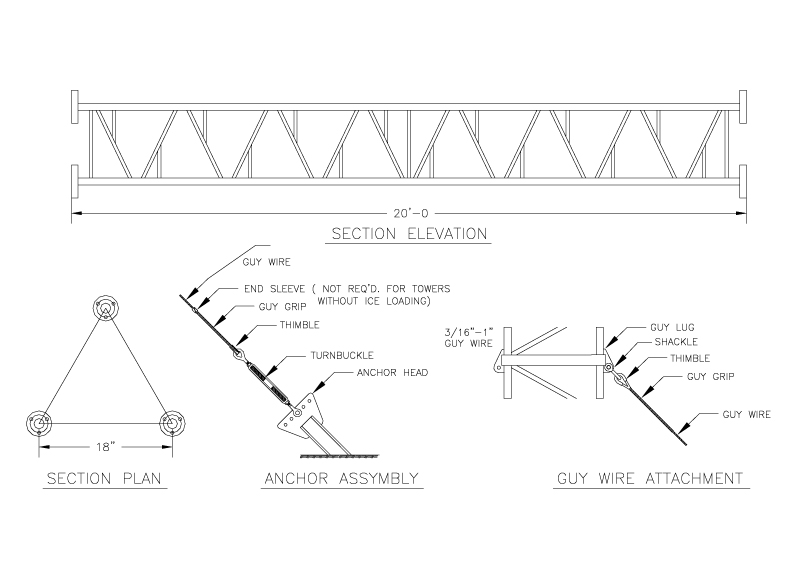

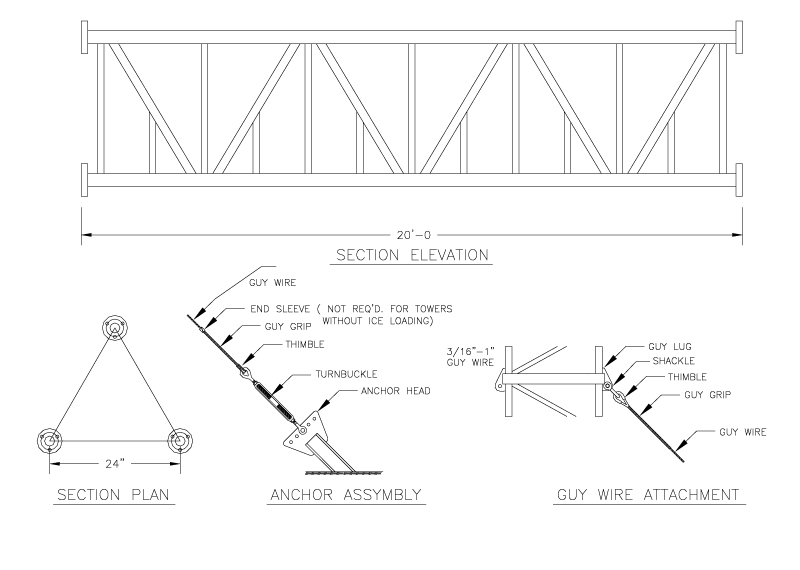

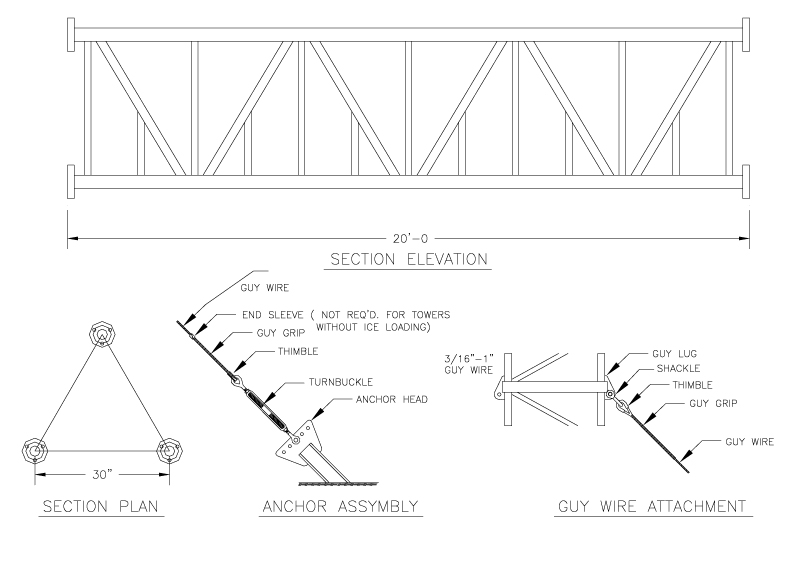

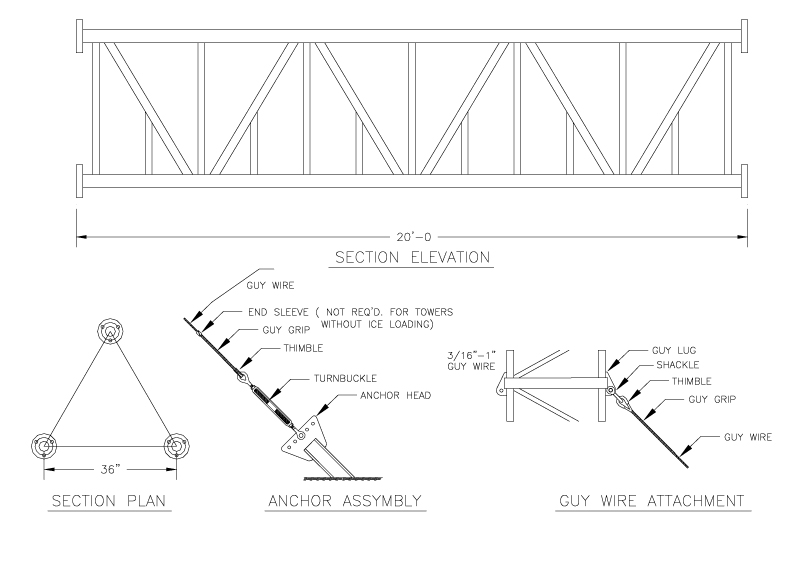

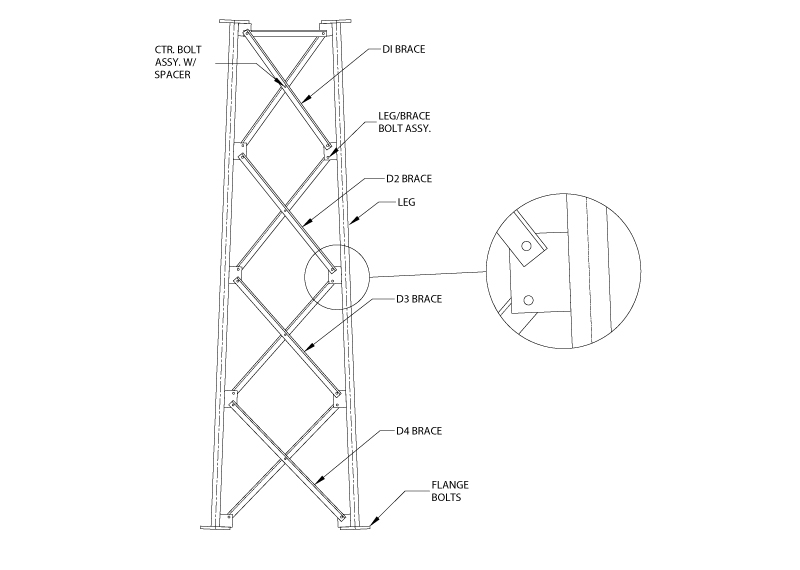

Each structure is fabricated from the ground up. Our fundamental guyed tower is welded with face widths ranging from 18″ through 60″. All towers are made from solid steel and welded by certified welders.

After fabrication, towers are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing.

Our standard guyed towers are secured with a pivot base and can reach heights up to 1,100 feet. The all welded design provides maximum tower stiffness, minimum twist/sway and bending. Towers come with integral wave guide clips and climbing ladder and are secured with heavy duty guy cable and hardware.

These towers can accommodate a variety of broadcasting, cellular, and microwave antennas. For antenna installation, we offer a wide variety of accessories and mounts.

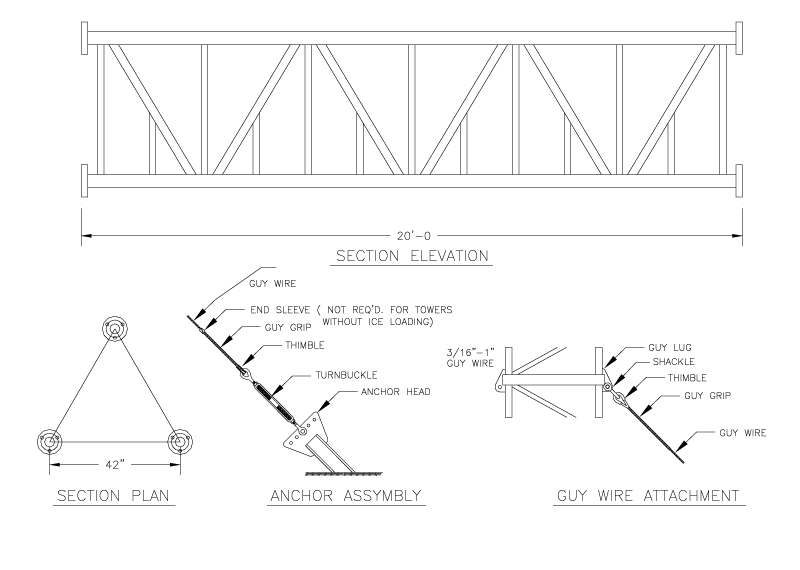

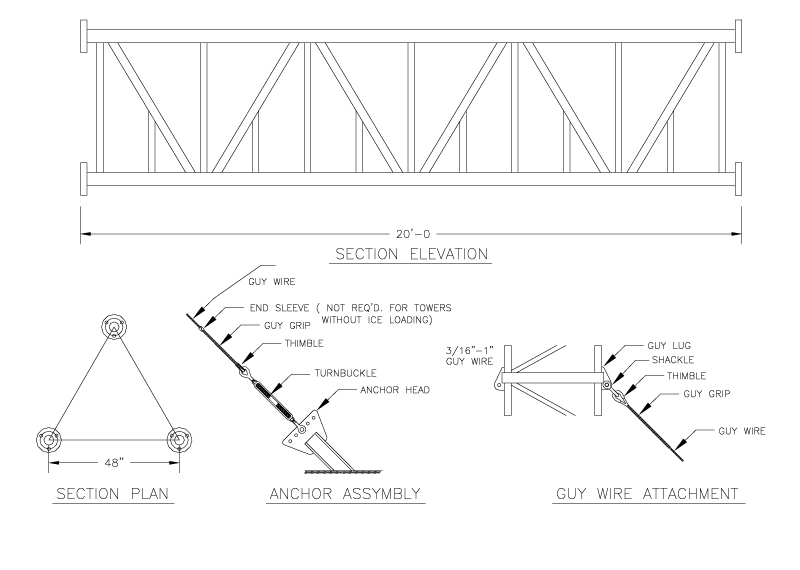

18SR Section Detail

24SR Section Detail

30SR Section Detail

36SR Section Detail

42SR Section Detail

SELF SUPPORT TOWERS

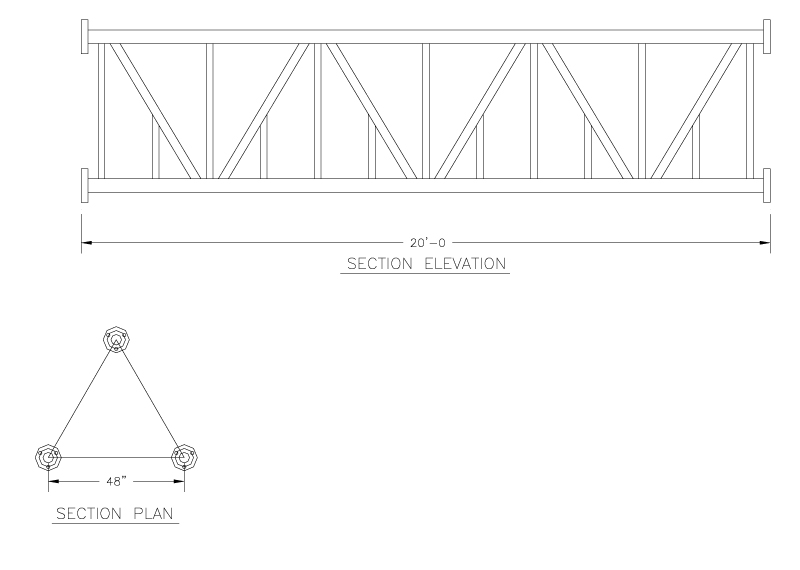

World Tower manufacturers the most cost-effective and easy to install Self Support tower systems that stand the test of time. Our Self Support towers are constructed of steel pipe or solid steel legs joined by angle iron cross members. Structures can reach heights of up to 500 feet.

During our quality control process, our production manager oversees the assembly of a face from each tower section. To other manufacturers, this may seem like a waste of time and resources but we believe it is this sort of attention to detail that ensures that tower installations run smoothly for all parties involved.

After fabrication towers are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing.

Self Support towers use a minimal space requirement. They can be designed for future loading and even structure height increases

As with our guyed structures, our self-support systems can accommodate a variety of broadcasting, cellular, and microwave antennas.

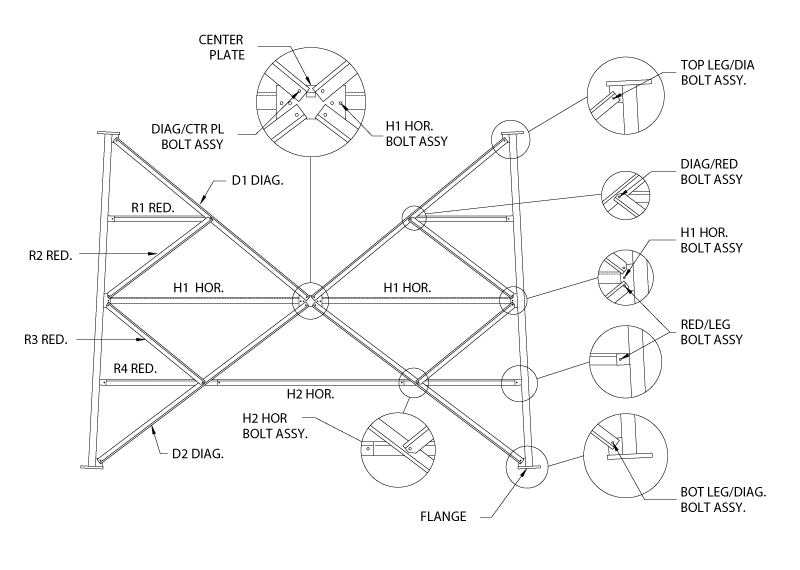

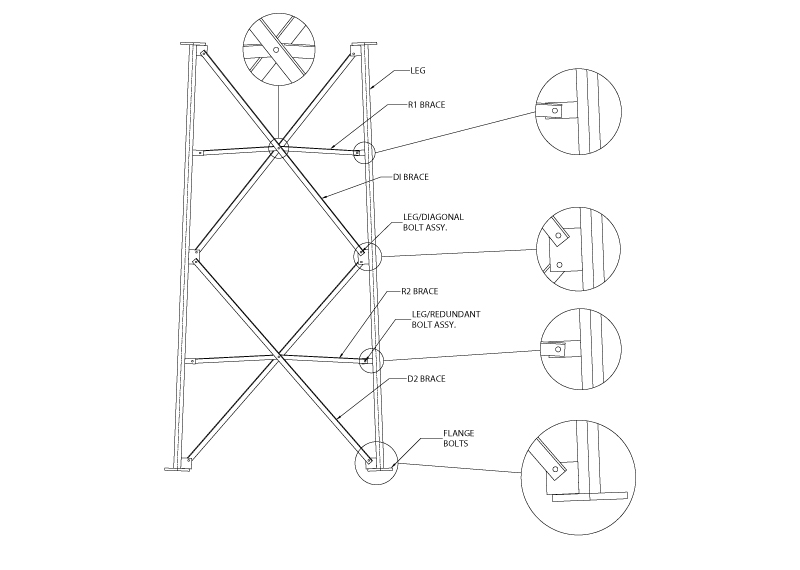

One Bay Section Detail

Two Bay Section Detail

Four Bay Section Detail

48SR UCS Section Detail

MONOPOLE TOWERS

World Tower provides a monopole constructed of heavy duty galvanized steel.

After fabrication poles are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing.

Monopole towers use a minimal space requirement. And with World Tower a solid and stable structure from which to add additional carriers.

These towers can accommodate a variety of broadcasting, cellular, and microwave antennas. For antenna installation, we offer a wide variety of accessories and mounts.

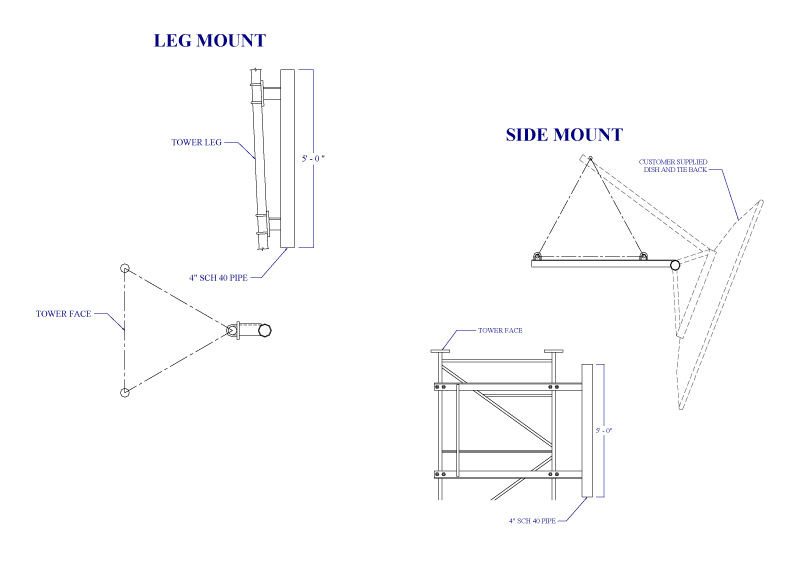

TOWER ACCESSORIES

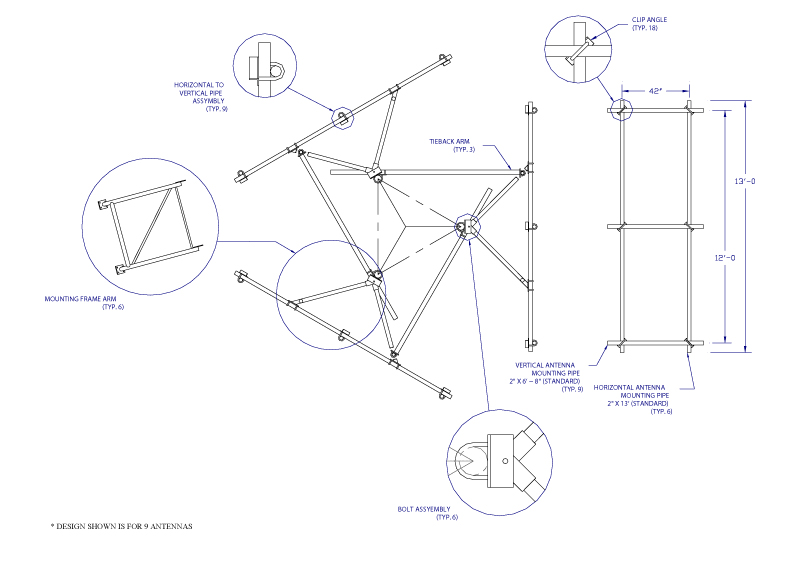

Sector Mounts

● Sector Mounts can Accommodate Antenna Configurations up to 12 Antennas

● Attaches to Towers with a Face Width from 36” to 72” Center to Center of Legs

● Variable Vertical Lengths of Antenna Mounting Pipes to Meet Your Particular Requirements

● Variable Horizontal Lengths of Antenna Mounting Pipes to Meet Your Particular Requirements

● Assembly Hardware Included

● Designed to Insure Factory Fit to World Tower Company, Inc. Towers

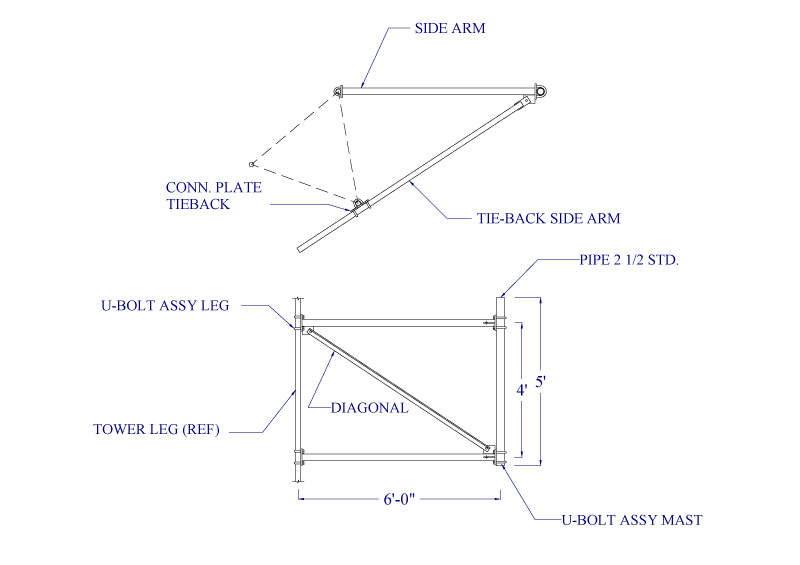

Side Arm Mounts

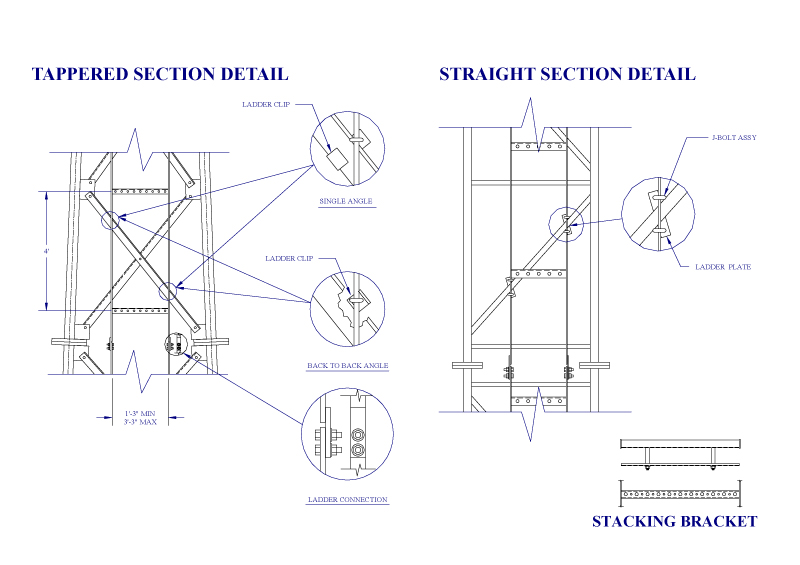

Waveguide Ladder

● 20’ Solid Welded Sections for Easy Installation

● Variable Ladder Widths Available from 15” to 39”

● 48” Separation Between the Ladder Supports

● Standard Snap-in holes are 3/4” at 2 1/2” spacing. Supports Also Available in other configurations as well.

● Add Stacking Brackets to Increase the Ladder Capacity

● Assembly Hardware Included

● Designed to Insure Factory Fit to World Tower Company, Inc. Towers

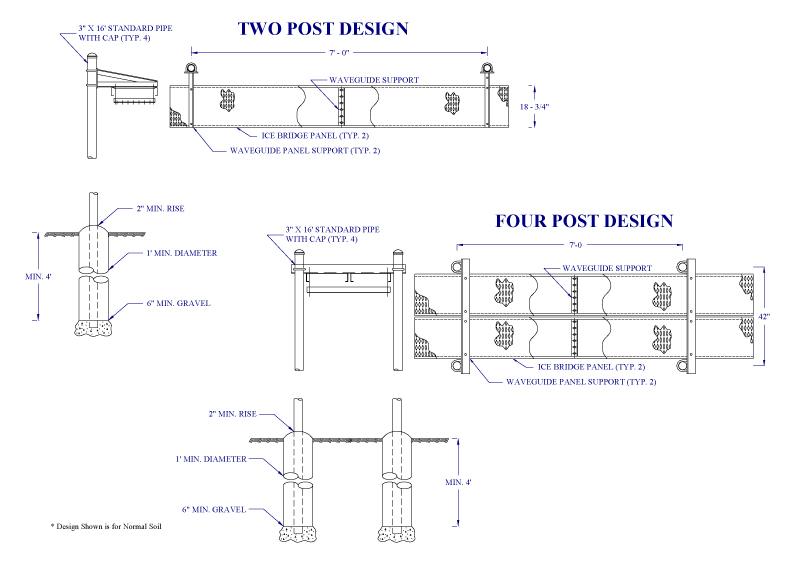

Ice Bridge Assembly

● Ice Bridges come in 10’ sections for installation convenience

● Ice Bridges can accommodate multiple line configurations to meet your individual needs.

● Assembly Hardware Included

● Designed to Ensure Waveguide lines are protected from the tower to your shelters

● Two-Post Design has Either a 18” or 24” Panel

● Four Post Design has Two Panels with Any Combination of the 18” or 24” Panels

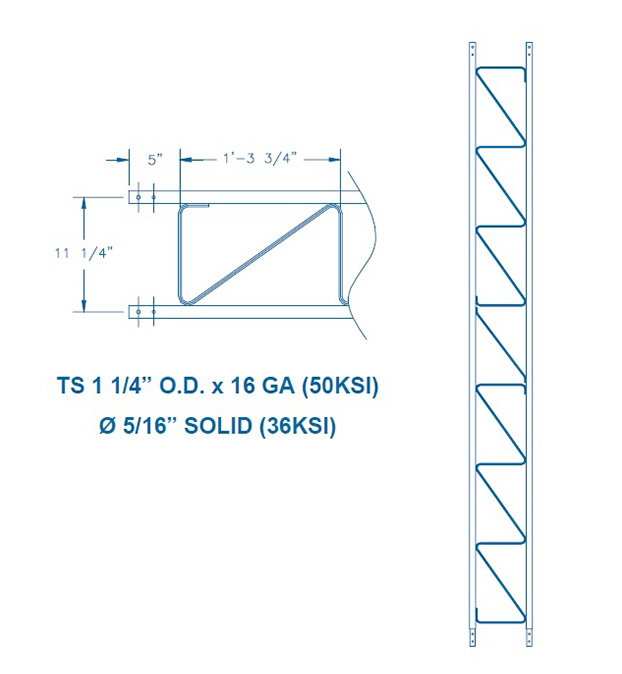

W25G TOWERS

The WG series was designed to offer a multi-use tower at an affordable price. These towers are all welded sections from high strength steel tubing and solid rod bracing for the highest quality.

Every structure is fabricated from the ground up. All towers are made from solid steel and welded by certified welders.

After fabrication towers are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures ensure years of maintenance free towers.

World Tower’s WG Series towers are secured with a pivot base and can reach heights up to 190 feet.

W25G Towers Catalog

MET TOWERS

World Tower provides the growing Wind Power Industry with the most reliable, economical MET tower systems in the business.

We design both Self Support and Guyed MET towers that come in a variety of tower heights (40M/50M/60M/80M). These structures are designed specifically to hold standard wind equipment.

Additional tower heights on request. Our design provides maximum tower stiffness, minimum twist/sway and bending. Towers come with integral wave guide clips and heavy duty guy cable and hardware.

After fabrication towers are delivered to the galvanizing facility to be Hot Dip Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures ensure years of maintenance free towers.

Inquire about the World Tower’s other MET tower services such as Technical Setup and Instrumentation Kits.

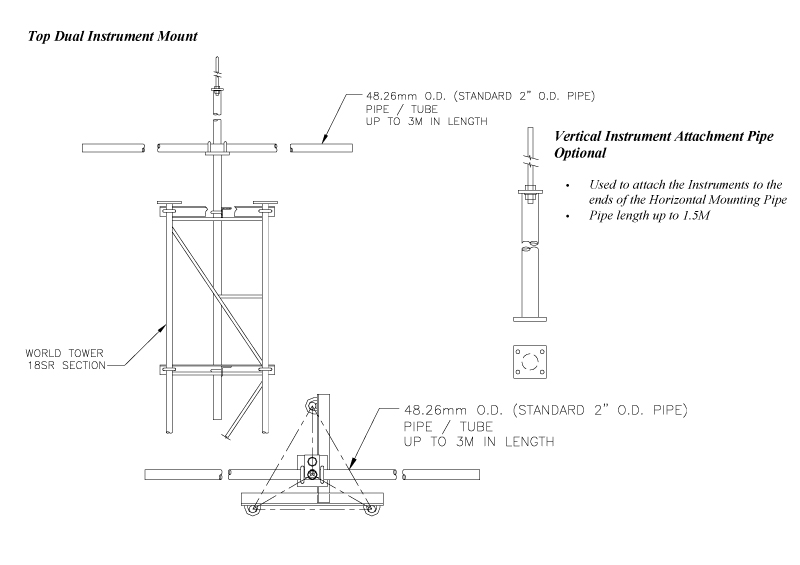

Top Dual Boom

Advantages Over Conventional Boom Mounts:

●Vertical and Horizontal Adjustments for Precise Location of Instrumentation

●Variable Horizontal Lengths and Pipe Diameter to Meet Design Requirements

● Retractable Horizontal Pipe for Easy Instrumentation Repairs

● Horizontal Pipe Designed for Minimal Instrumentation Deflection and allowing more accurate Readings

● Designed to Ensure Factory Fit to World Tower Company, Inc. Towers.

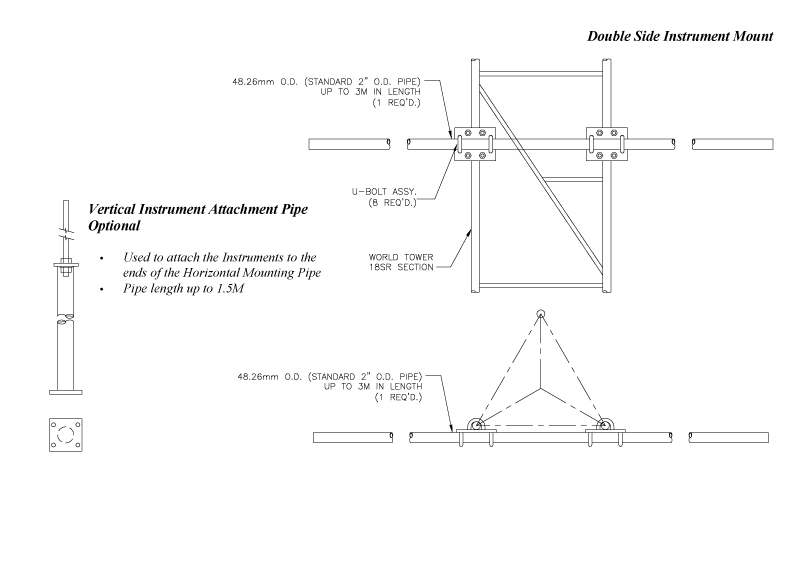

Double Side Boom

Advantages Over Conventional Boom Mounts:

● Vertical and Horizontal Adjustments for Precise Location of Instrumentation

● Variable Horizontal Lengths and Pipe Diameter to Meet Design Requirements

● Retractable Horizontal Pipe for Easy Instrumentation Repairs

● Horizontal Pipe Designed for Minimal Instrumentation Deflection and allowing more accurate Readings

● Designed to Ensure Factory Fit to World Tower Company, Inc. Towers.

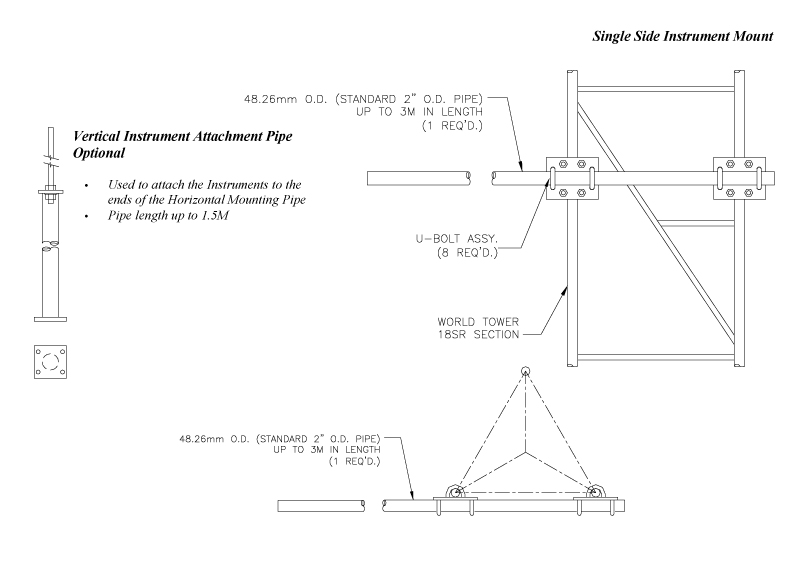

Single Side Boom

Advantages Over Conventional Boom Mounts:

● Vertical and Horizontal Adjustments for Precise Location of Instrumentation

● Variable Horizontal Lengths and Pipe Diameter to Meet Design Requirements

● Retractable Horizontal Pipe for Easy Instrumentation Repairs

● Horizontal Pipe Designed for Minimal Instrumentation Deflection and allowing more accurate Readings

● Designed to Ensure Factory Fit to World Tower Company, Inc. Towers.

DOWNLOAD FLYER: OFF-Grid System Flyer

DOWNLOAD FLYER: 50 Meter MET Tower KIT

DOWNLOAD FLYER: 60 Meter MET Tower KIT

DOWNLOAD FLYER: 80 Meter MET Tower KIT

DOWNLOAD FLYER: 80 Meter SS MET Tower KIT